Technique:

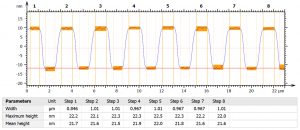

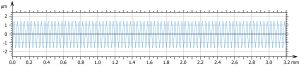

With a noise level of a couple of nanometers and three height ranges (13, 131 and 1048 µm), our profilometer allows us to measure height differences from 5 nm to 1 mm. The instrument can handle samples as large as 8 inches in diameter and as heavy as 5 lbs.

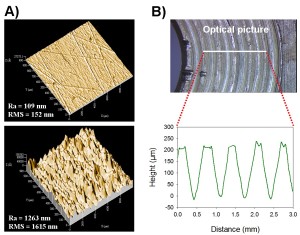

The applications of the instrument cover roughness and waviness estimation and step height measurements. By scanning a series of tracings, one can also obtain a 3D topographic image of the surface, from which any scan lines can be isolated for analysis.

Instrument:

KLA-Tencor P-17 Surface Profiler

System Capabilities:

Selected Applications in Industry: