Request for analysis:

A local manufacturer was experiencing blister defects occurring in foam rubber pieces used in door trim.

Objectives:

Methodology:

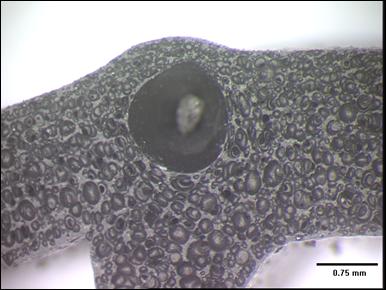

The defects were examined in plan view and in cross-section. The cross-sections showed the presence of a white particle in a void. Selected particles were then examined using energy dispersive X-ray (EDX) spectroscopy and Fourier transform infrared spectroscopy (FTIR).

Results of the study:

The optical microscope image presented in Figure 1 shows a white particle at the centre of a cross-sectioned blister defect. Elemental analysis (not shown) of the defect particles showed mainly carbon, oxygen, silicon, calcium, and magnesium. Trace levels of potassium, sulphur, sodium, aluminum and zinc were also observed occasionally.

A white particle was also analyzed by Fourier transform infrared spectroscopy (FTIR) using the microscope in transmission mode. FTIR is an optical spectroscopy technique that allows one to determine the bonding present in a material. The spectrum of the particle is shown below in red (Figure 2). A comparison with a match from our spectral library shows that the defect consists of two components, talc (blue) and sodium stearate (black).

Based on the FTIR and EDX analyses, the white particles are a mixture of talc, sodium/calcium stearates and a small amount of calcium carbonate. The white particles are most-likely agglomerations of compounds normally found their process.

Figure 1: Optical microscope image of the blister defect in cross-section.

Figure 2: FTIR spectra of the defect particle from the blister, sodium stearate and talc.