Request for analysis:

Plastic mouldings are attached to painted surfaces of an automobile side panel using a foam adhesive strip. During application at an assembly facility it was noted that intermittent failures of the adhesive were occurring and, as time progressed, full failure of all mouldings were found.

Objectives:

Methodology:

The foam adhesive surfaces, painted side panels exhibiting full failure and intermittent failure, as well as known good reference panels were analysed by X-ray photoelectron spectroscopy (XPS). XPS is a surface sensitive technique that can detect all elements except hydrogen and helium and probes the surface of a sample to a depth of 7 to 10 nanometres depending on the sample composition. High-resolution XPS spectroscopy can give chemical state information on the elements present.

Results of the study:

XPS analysis of the foam adhesive surfaces did not reveal any significant contamination among the various samples collected. This suggests that the foam adhesive is not contributing to the failure.

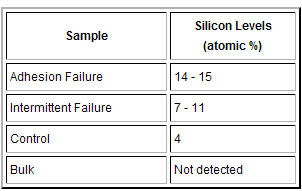

The painted side panel surfaces were then examined. The XPS spectra show significant changes in the amount of silicon present. The silicon concentrations are summarised in the Table 1. The reference panels have approximately 4 atomic % silicon at their surface, the intermittent failure samples show between 7 to 11 atomic % silicon and the full adhesion failure samples show between 14 to 15 atomic % silicon.

High-resolution silicon 2p spectra of failed painted surfaces gave a binding energy of 102.3 eV (charge corrected for carbon 1s signal (C-C, C-H) at 285.0 eV). This suggests the presence of silicone (e.g. polydimethylsiloxane).

Silicone is added to automotive paint formulations for a number of reasons; as an anti-cratering agent, to control “orange peel”, to improve flow and levelling and as an antifoaming agent. However, the amount present must be precisely controlled. When excess silicone is present at the surface of the paint, adhesion is impeded. In this case, excess silicone had been added to a specific lot of clearcoat resulting in adhesion failure of the foam adhesive to the painted side panel.

Figure 1: XPS survey spectra comparing silicone levels on painted side body panels.

Table 1: Summary of silicone levels on painted side body panels.