SSW recently installed a Zeiss Xradia 410 Versa Micro-CT and a Deben CT500 mechanical testing unit (soon to be upgraded to CT5000). With this instrument, SSW scientist Dr. Heng-Yong Nie has been collaborating with the research group of Professor Yu Liu at Jiangnan University to develop analytical approaches to understanding mechanical responses of 3D printed elastomer structures to compressive pressures. A visiting graduate student from Jiangnan, Wei Xu, carried out part of this work on pressure sensitive devices during his visit to SSW from December 2019 to March 2020.

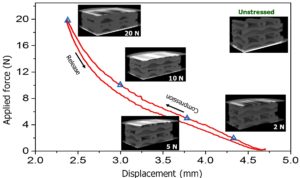

Shown below are a force-distance curve for a 3D printed sample constructed with hollow silicone filaments and Micro-CT results of the sample under applied forces of 2 – 20 N. Since the dimensions of the sample are obtainable from the Micro-CT results, one can deduce the stress-strain curve from the force-distance curve, from which Young’s modulus can be estimated. Our approach using Micro-CT and in-situ mechanical testing provided valuable insights on building pressure sensors and other electric sensors via 3D printing technology.